Search

Search

Industry process control Gas system

Industry Gas Sensor

Industry Gas Analyzer

Gas Analysis System

Marine product line

Environmental protection analysis system

Customized solutions for process control

Fumigation gas detection

Nuclear safety monitoring

Medical Gas Supply & Monitoring

The SGS-200 furnace gas continuous analysis system has a special design for gas sampling probes, equipped with water cooling devices and automatic cleaning devices. The system is equipped with two gas sampling probes: the two probes can automatically cycle and switch, ensuring the stable operation of the smelting process furnace gas analysis system and continuous measurement and analysis of furnace gas composition. The SGS-200 gas online monitoring system consists of a sampling probe unit, a probe backwash unit, a preprocessing unit, and an instrument control unit. The sampling probe unit and probe backwash unit need to be installed on the flue, while the preprocessing unit and instrument control unit are integrated in the "analysis host cabinet". The pretreatment of the sample gas is equipped with filter accuracy which can reach 0.1μm. The sample gas with ultra-clean and stable flow rate meets the requirements of the high analytical accuracy and long-term reliability of the analytical gas system. This analysis system has its own independent power control and logic control functions, which control the detection, blowback, self-diagnosis and other functions of the measuring device, without the need for system control or manual operation outside the device. SGS-200 system has a system fault alarm contact output function, which can transmit signals to the DCS system. At the same time, the analysis system has analog or RS485 signal output.

SPS-200 is a gas analysis system specially designed by SIGAS for monitoring the concentration of carbon monoxide, carbon dioxide, oxygen, and hydrogen sulfide in the furnace of power plants. SPS-200 is composed of sampling probe unit, probe blowback unit, pretreatment unit and instrument control unit. The sampling probe unit and probe blowback unit are installed on the flue, while the pretreatment unit and instrument control unit are integrated in the "analysis main cabinet". The analysis system is a two-sampling system, which uses a pre-processing system and an analysis system to detect gas concentration data at two sampling points in turn. The system can continuously and accurately complete the sample gas analysis, with good selectivity, avoid the interference of background gas, the system output 4~20mA current signal. The analysis system has its own independent power control and logic control functions, and controls the detection, back blowing, self-diagnosis and other functions of the measuring device, without system control or manual operation outside the device. The analysis system has the function of system fault alarm contact output, which can send the signal to DCS system. At the same time, the analysis system has analog or RS485 signal output. Product Advantages: The system cabinet integrates the condensing system, automatic electrical control and gas analyzer. The signal output ranges from 4 to 20mA. The analytical instrument in the system has the function of self-diagnosis and fault alarm of main instrument components. pretreatment of the sample gas is equipped with filter accuracy which can reach 0.1μm. The sample gas with ultra-clean and stable flow rate meets the requirements of the high analytical accuracy and long-term reliability of the analytical gas system. The DC motor is used to clean the small holes regularly to avoid the ash accumulation of the small holes and ensure the continuous and stable operation of the system. Specification: Type Item Parameter Specification Measurement range CO(dual-range):0~10000ppm,0~300000ppm; H2S:0~1500ppm;O2:0~25%;CO2:0~100% Accuracy 1%FS linearity error ≤±1%FS Span Drift ≤±0.5%FS Zero Drift ≤±0.5%FS Maintenance Cycle 1 time / 3 months Output signals analog output 4-20mA(Isolated, Max Load 750Ω) Interface RS485 or RS232 Working condition Power 220VAC Working tem. 5℃-40℃

SGS SGS-204 Blast furnace gas measurement system includes sampling probe, gas pre-treatment unit, analysis unit and instrument calibration unit. The SGS type system basis of the mature measurement technology and on-site experience, has the advantage of anti-corrosion, clogging, safety and reliable, real-time sampling, fast response and high precision analysis. It configured to fulfill different industry gas measurement requirement which offer high performance, reliability, low maintainability to the industry gas analysis application. Product Advantages: With Auto-calibration function to insure stable measure CO/CO2/H2/CH4/O2, decrease the infect of measurement drift. System cabinet is made by explosion-proof stainless steel, which equipped with gas pre-treatment, electrical control and gas analyzers, with 4~20mA output signal. System equipped with self-diagnose function, offer different alarm signal for customer reference. The system components and sampling head are provided with a cleaning (blow back) system where they are in contact with the measured gas.To prevent contamination of analytical instrument components. When the cleaning (back blow) system fails, an alarm is displayed on the system and the isolation unit is activated to protect the monitoring components. The probe and other parts in contact with the measured or corrected gas are composed of corrosion resistant materials. All sampling system components installed on piping are made of Hastelloy C-276, PTFE, or stainless steel of the same corrosion resistance and shall operate continuously and normally up to the maximum gas temperature of piping. Gas pre-treatment system insure to complete the sample gas purification, dust removal, dehumidification, filtration accuracy up to 0.1μ, to fulfill the requirements of sample gas for the analyzer, to offer clean, constant temperature, stable flow of sample gas flowing into the analyzer, so as to ensure the analysis accuracy and long-term reliability of the analyzer. Fulfill multi-gas measurement, built-in real-time component interference calibration function to remove cross interference caused by various mixed gases; Equipped with zero/span calibration, third point calibration, and the third point calibration value is limited between 35%... 75%, to guarantee good linearity; Specification: Technology Specification Measurement Range CO:0~50% CO2: 0~10% H2: 0~20% O2: 0~1% CH4:0~10% N2:0~100% Response time T90<15s Accuracy 0.01% Linearity ≤±0.5%FS Span drift ≤±0.5%FS Zero drift ≤±0.5%FS Maintain 1 time/season Output signal Analogue Output 6 Channels 4-20mA (Isolation, Max load 750Ω) Analogue Input / Communication RS232/RS485 Working Condition Power Supply 220VAC Working Temp. 5℃-45℃

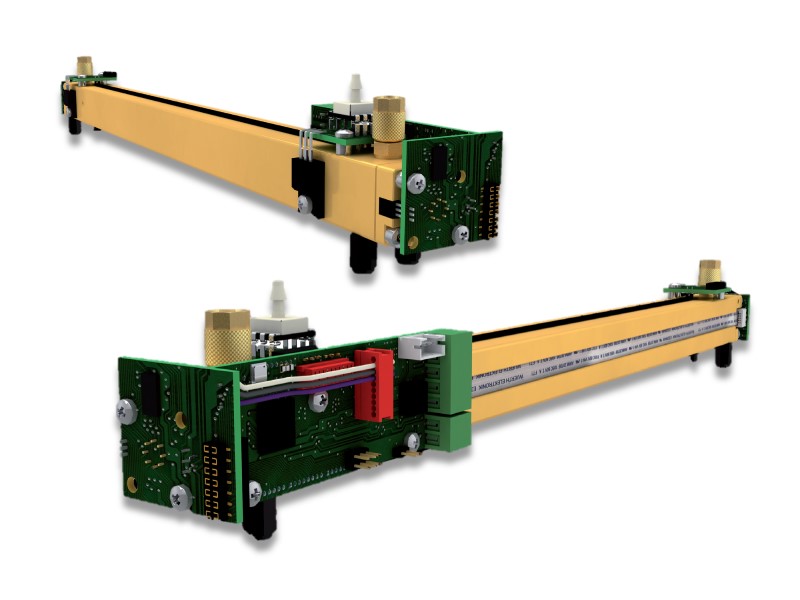

For gases with very low absorption the SILAREX multi-gas sensor housing will be with gold plated surface to reach the maximum of signal by the IR refelction of the gold surface. And the gas Inlet and Outlet are fitted with gas line connectors to allow perfusion of the SILAREX. Tubing with an internal diameter of 3 mm and external diameter of 5 mm is needed to connect up to the measurement cell. Ensure that tubing is securely attached to the inlet and outlet connectors. Meanwhile we have equipped SILAREX with heated aluminium Housing to make the stable temperature of sensor, to reduce the fluctuation of measurement date due to the unstable environment temperature, which is special good for Gas Emission measurement.. Also with pressure sensor to reduce the gas flow influence. SILAREX is the right product for all kind of industry stable gas measurement application. Product Advantages: Ready to use calibrated On board cross compensation On board pressure compensation Modbus ASCII/RTU, autobaud, autoframe Status indicated by LED Very low warmup time and hugh temperature stability with cased version Very small cuvette volume Specification SILAREX CO2 25Vol.% CO 1000ppm 340mm (cased) Digital Resolution (@zero) CO2 20Vol.% 0.01Vol.% CO 1000ppm 0.1ppm Detection Limit (3sigma) CO2 0.1%[FS] CO 0.5%[FS] Cross Sensitivity CO2 to CO < 10ppm @ 20Vol.% CO2 SO2 to CO < 10ppm @ 100ppm SO2 NO to CO < 10ppm @ 100ppm NO NO2 to CO < 10ppm @ 100ppm NO2 CH4 to CO < 30ppm @ 1Vol.% CH4 CH4 to CO < 150ppm @ 5Vol.% CH4 SO2 to CO < 25ppm @ 500ppm SO2 SO2 to CO < 45ppm @ 1000ppm SO2 NO to CO < 40ppm @ 1000ppm NO Specification SILAREX CO2 20Vol.% NO 2000ppm SO2 1000ppm 340mm (cased) Digital Resolution (@zero) CO2 20Vol.%: 0.01Vol.% NO 2000ppm 1ppm SO2 1000ppm 1ppm Detection Limit (3sigma) CO2 0.1%[FS] NO 1%[FS] SO2 1%[FS] Cross Sensitivity CO2 to SO2 < 10ppm @ 20Vol.% CO CO2 to NO < 20ppm @ 20Vol.% CO2 SO2 to NO < 20ppm @ 1000ppm SO2 NO to SO2 <2ppm @ 1500ppm NO DP to NO < 30ppm @ 4.5 ±1°C DP to SO2 < 20ppm @ 4.5 ±1°C Specification: Detection Principle NDIR (Quad Beam) Measuring Range See List Gas Supply Flow Dimensions See Mechanical Data Hose connection 3mm internal, 5mm outside Heated Tem. Internal 42°C / SILARIX Cased 45°C Response time (T90) < 8sec @0.7 l/min (default) Repeatability ≤ ±1 % FS Linearity Error ≤ ±1 % FS ( or ≤ ±1.5 % FS depend on version) Stability < ±2% [FS] @1000h Operating Temp 0 °C up to 40 °C / SILARIX Cased 45°C Storage Temp -20 °C up to 60 °C Ambient Humidity 0 % up to 95 % rel. Humidity (Non-condensing) Ambient Air Pressure 800 ... 1150 mbar Warm up Time < 2 minutes (Cold start) < 30 minutes according to heat isolation and environment Tem. Flow 0.2up to 1,0 L / min (const flow) Gas Inlet Tem. 2 ... +42°C / SILARIX Cased 2..45°C Gas Inlet Humidity 5°C max ±1K (need cooler) Diginal Output Signal Modbus ASCII RTU TTL2400-115.200 auto Baud/ auto Frame Operation power 24 VDC ±0.3V Driven Current 240mA / max 1.5A during Heating Power Consumption < 800 mW / max 36W during Heating

Our NDIR gas sensor FLOWEVO / FLOWEVO plus as basis the IR principle uses the individual absorption spectrum of the gas to be detected and specifies the concentration by the precise quantitative analysis. Because all measured gases absorb IR radiation in a different spectrum a so called “fingerprint” is given which ensures a selective characterization with less cross sensitivities. An integrated evaluation electronic delivers finally an easy to use concentration signal and compensates all temperature- and drift effects. All FLOWEVO / FLOWEVO plus are available in an industry suitable case with integrated thermal isolation. The FLOWEVO / FLOWEVO plus housing is made of aluminum to protect the sensor from mechanical damage and is with fitted with gas line connectors (inlet and outlet) to allow perfusion of the FLOWEVO / FLOWEVO plus The Case is equipped with a fiber heat isolation to ensure there will be no condensing steam inside the housing at hig environment humidity . Product Advantages: Highly selective: low cross sensitivity to other gases Long lifetime: up to 10 years Fast response time:T90 < 3s (fast Mode) Small drift over time: long calibration cycles Low cost of ownership: sustainable technology All FLOWEVO / FLOWEVO plus are available as cased version with thermal isomaltion Product Advantages FLOWEVO plus: Extremely low noise at lowest response time Integrated active heating to reach highest stability and prevent any condesing humidity inside RS232 and RS485 digital interface Different analog interfaces available Active cuvett pressure compensation available Standard 24VDC Power input FLOWEVO FLOWEVO plus Specification FLOWEVO / FLOWEVO plus: FLOWEVO FLOWEVO plus Detection Principle NDIR (Dual Beam) Measuring Range See List Gas Supply Flow Dimensions See Mechanical Data Hose connection 3mm internal, 5mm outside (Standard) Readout NoiseABS (Typical) ±0.1%FS@ T90 <14sec (standard)±1%FS @ T90 <3sec (fast Mode) ±0.075%FS @ T90 < 3sec Readout Cycle Max 2.5Hz Max 10Hz Response time (T90) T90 <14sec (standard) T90 <3sec (fast mode) T90 <3sec Digital Resolution(@zero) 1 ppm ...0.1 Vol.% Detection Limit (3sigma) ≤ 1 % FS(typically) Repeatability ≤ ±1 % FS Linearity Error ≤ ±1 % FS ( depend on type) Stability (zero) ≤ ±2 % FS during 12 month Stability (span) ≤ ±2 % FS during 12 month Temperature Drift. (zero) ≤ ±0,1 % FS per °C Temperature Drift. (span) ≤ ±0,15 % FS per °C Pressure Drift. 0.1 % up to 0.2 % Value per mbar Operating Temp 0 °C up to 50 °C Storage Temp -20 °C up to 60 °C Ambient Humidity 0 % up to 95 % rel. Humidity (not condensing ) Ambient Air Pressure 800 up to 1200 mbar Warm up Time < 2 minutes (cold start ) < 30 minutes full specification Flow 0.1 up to 1.0 L / min (const ) Digital Output Modbus ASCII RTU TTL2400-115.200 auto Baud/ auto Frame Single Wire 2400-115200 Auto baud rate, auto frame - Free ASCII - Modbus ASCII - Modbus RTU - EVO Modbus ASCII - EVO Modbus RTU 9600, 8, none, 1 - SCII Modbus RTU Option : Analog Output Optional with external Controller0 / 4 … 20 mA (With S-Connect)0 / 0.2...1V (With S-Connect V) Optional internal0 / 4 … 20 mA Isolated (3kV/rms)4-20mA , max load 600Ω 0-2VDC , min resistance load 2kΩ 0-5VDC , min resistance load 2kΩ 0-10VDC , min resistance load 2kΩ Option : Digital Output Optional with external ControllerRS 232 (With S-Connect) RS 485 (With S-Connect RS485) Integrated RS232RS485 Operating Voltage 3,3 to 6 V DC ± 5 % 10-26VDC, recommend 24VDC Drive Current Not Heated< 240mA@5V ( average ) HeatedMax 1.3A @24V Power consumption Not Heated< 800 mW Heated<11 W @24V for Type II/III <9 W @24V for Type I (73) <17 W @24V for Type I (113mm...153mm) <21 W @24V for Type I (233mm) <31 W @24V for Type I (333mm) Heating Optional with external heat controller Internal for all types of FLOWEVO Pressure Compensation Environment Pressure Compensation Environment Pressure Compensation Cuvette Pressure Compensation (optional) Optional Customized Firmware No yes

The entire structure of NDUV gas measurement technology, can be disassembled to make the maintenance/service easier. The different devices are sealed with O-Ring joining. The stainless steel sample cell is coated with a protection layer. The length is 100mm. For the combined detection of NO, NO2 and SO2 three different light sources are integrated. For example, we use AlGaN-LED for the UV light source which can cover 360-230nm wave length. For enhance the life time of the light source, we use special control board, which can let the light source achieve more than 3 years life time, which solve the well-know problem of shortcoming of UV light source. S-Ultra.Sense is suitable for all kind of complex industry environment, special has good performance in low range CEMS measurement, which can good measure NO and NO2 without transition device. Standard gas measurement type (other gas and range please contact us): S-UltraSense NO 0-300ppm S-UltraSense O3 0-100ppm S-UltraSense O3+CnHm O3 0-25ppm / CnHm 0-500ppm S-UltraSense H2S H2S 0-100ppm / 0-500ppm / 0-1500ppm / 0-5000ppm S-UltraSense H2S (Background gas CH4) H2S 0-100ppm S-UltraSense NO/NO2/SO2 NO 0-300ppm / NO2 0-200ppm / SO2 0-200ppm S-UltraSense SO2/NO2 SO2 0-1000ppm / NO2 0-1000ppm S-UltraSense NO2/N2O NO2 0-2000ppm / N2O 0-2000ppm S-UltraSense N2O 0-1000ppm S-UltraSense SO2 0-100ppm / 0-500ppm S-UltraSense SO2 dual range 0-1000ppm (LDL 1ppm), 0-30000ppm(LDL 20ppm) Product Advantages: Fast readout time ≈ 200ms High dynamic range No cross talk to H2O Rugged sensor design Demountable construction Gas tight O-Ring sealing Low power consumption <1 Watt @ 24 VDC Different Interfaces (RS 232, CANopen) Connection of two optical benches Specification: Measurement Technology NDUV Heating Tem. 42.10 T90 Response time <3s@1L/min Digital resolution(@zero) 1ppm...0.1 Vol.% Detection Limit (3sigma) ±0.5%FS Repeatability ±1%FS Linearity Error ±1%FS Stability (zero) ±1%FS Stability (span) ±1%FS Temperature Drift. (zero) ±1%FS per 10K(典型值) Temperature Drift. (span) ±1%FS per 10K(典型值) Pressure Drift. ±0.015% /mbar Operating Temp 10...40℃ Storage Temp -10...60℃ Ambient Humidity 0 % up to 95 % rel. Humidity (not condensing ) Ambient Air Pressure 800...1200 mbar Warm up Time <60min (related to environment Tem.) <30min @20℃ environment Tem. Start time <2 min (reach the heating Tem.) Flow gas Tem. -2℃...40℃ Flow gas Humidity Max. 10℃ (not condensing) Gas flow 0.2...1L/min (stable flow) Output Signal RS232 9P-Sub-D 和 2x5pin 2.45mm 接头 Operating Voltage 24VDC±0.3V 3A Power consumption 4W (Heating max. 55W)

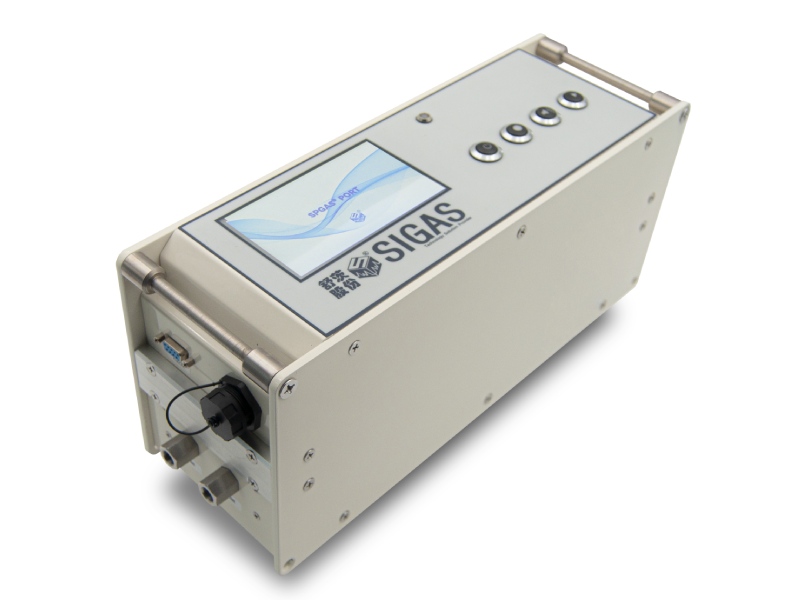

Industry Gas Analyzer Application: Industry Process control ( Semiconductor, electric power, chemical industry, metallurgy, etc.) Environment pollution control Service and testing Waste gas analysis Process gas analysis Air quality control TOC value measurement Blast furnace gas detection Garbage landfill Tunnel gas detection Product Advantages: SA-200 with touch screen control, all function in one hand. Three screen switch function Screen 1: Value status, include menu and error information Screen 2: real-time gas concentration and value change Screen 3: real-time gas concentration curve Calibration menu, alarm set with password control Function of zero, span and third point calibration to get better linearity. Free to choose English and Chinese menu one button with “back to factory setting” to provide wrong operation. Specification: Product Type S-ANALYZER 200 V5.0 Channel - Max. 5 measured Gases - Configuration information includes - measuring gas type - measurement range - measuring Error Response time General:<25s (t90 @60 L/h Constant Flow) Warm up Time 3min~30minn @amibent 20℃ (accord different detector configuration) Digital Res. (@zero General: - 0.01Vol.% in case of percent range (e.g. 0.001Vol.% for BMBT O2 channel) - 0.1 µmol/mol in case of µmol/mol range Operation Handling Touch panel, 5.6” TFT Analog Output 4mA~20mA (normal operation) 2mA (in warm-up or status alarm) Analog Output Range Default is 4mA for lower range, and 20mA for upper range. User setable. Relay contact output Relay out quantity: x6 With relay out assignment for: 1. x1 instrument error alarm 2. x1 sample gas control valve relay signal for auto. cali. 3. x1 auto. cali. zero gas supply control valve relay signal 4. xN (N is channel quantity) auto. cali. span gas supply control valve relay signal 5. xN (N is channel quantity) gas concentration upper/lower alarm Relay Property 1A contact (250V AC/2A, resistive load) Communication Standard RS232 (DB-9 female) RS485 with modbus protocol. Operating Voltage 98~242V AC, 50/60 Hz. Power consumption <125W Power inlet EN60320 C1 Fuse Fuse Current: 3A ,Blow Characteristic: Fast Acting Fuse Size Metric: 5mm x 20mm Case Protection Level IP41 (EN60529) Weight typical approx. 10kg (w/o package) approx. 19kg (w/ package) Gas Inlet Flow 0.4~0.8 L/min (Flow fluctuations ≤0.02 L/min) Inlet Gas Temp. 5~35 ℃ Inlet Gas Pressure 116kPa (max) Moisture in Gas • not condensing • inlet gas dew point:5℃±0.1℃ (This item is required when measure channel include NDIR SO2 and/or NO) Dust in gas flow 100µg/m³, ≤1µm Zero calibration gas 99.999Vol.% N2 (typical) 3th point(middle point) calibration gas range Allow range: 0.375*FS~0.625*FS Span calibration gas range (user calibration) Allow range: 0.75*FS~1.25*FS

Industry ATEX Gas analyzer Application: Industry Process control ( Semiconductor, electric power, chemical industry, metallurgy, etc.) Environment pollution control Service and testing Waste gas analysis Process gas analysis Air quality control Garbage landfill Tunnel gas detection Product Advantages: The sensor of S-ANALYZER ATEX can be chosen by customer according to application The explosion - proof chamber has passed 100% hydraulic test. Equipped with explosion proof certified cable gran head and air connection Equipped with flow meter window, the flow meter can be integrated in the explosion-proof analyzer Integrated DIN guide-type terminal for easy field maintenance Internal cables are 100% marked for easy maintenance Modular design to reduce potential maintenance costs The same user interface design as SIGAS non-explosion-proof S-Analyzer 200 series to reduces user learning costs The explosion-proof box is made of aluminum alloy, which is of better consistency, lighter weight and better flameproof performance Specification: Product Type S-ANALYZER 200 ATEX V5.0 Channel Max. 5 different gases in mixture •Configuration refer analyzer type plate or inspection report. •Gas configuration information includes - Measuring gas type - Measurement range - Measuring Error Response time General:<25s (t90 @60 L/h Constant Flow) Warm up Time 3min~30min (accord different detector configuration) Digital Resolution (@zero) General: - -0.01Vol% in case of 0-10Vol.% range - -0.1Vol% in case of 0-100Vol.% range - 0.1 µmol/mol[ 1 µmol/mol = 1 ppm] in case of µmol/mol range Operation Handling explosion proof buttons Analog Output 4mA~20mA (normal operation) 2mA (in warm-up or status alarm) Analog output channel quantity same as gas measure channel quantity Permissible load resistance 250Ω~350Ω Relay contact output Relay out quantity: x6 With relay out assignment for: •x1 instrument error alarm •x1 sample gas control valve relay signal for auto. cali. •x1 auto. cali. zero gas supply control valve relay signal •xN (N is channel quantity) auto. cali. span gas supply control valve relay signal •xN (N is channel quantity) gas concentration upper/lower alarm Relay Property 1A contact (250V AC/2A, resistive load) Gas Connection NPT 1/8” female Operating Voltage (198~242)V AC, 50/60 Hz, power consumption <125W Cable gland Explosion proof cable gland TDJT-15 ∅6~∅13mm Fuse Fuse Current: 3A ,Blow Characteristic: Fast Acting Fuse Size Metric: 5mm x 20mm Ex Level ExdIICT6 Gb (containing C2H2) Certificate No.: GYB17.1096X The product has been inspected by the National Instrument and Explosion Safety Supervision and Inspection Station (NEPSI) and meet the following standards: GB3836.1-2010 Explosive atmosphere Part 1: Equipment General requirements GB3836.2-2010 Explosive atmosphere Part 2: Equipment protected by flameproof enclosure "d" Weight ~50Kg (typical) Gas Inlet Flow (0.4~0.8)L/min (Flow fluctuations ≤0.02 L/min)Refer to specific addendum for integrated sensor module Inlet Gas Temp. (5~35)℃ Inlet Gas Pressure (76~116)kPa Moisture in Gas • not condensing • inlet gas dew point:5℃±0.1℃ (This item is required when measure channel include SO2 and/or NO) Dust in gas flow 100µg/m³, ≤1µm Zero calibration gas 99.999% N2 3th point(middle point) calibration gas range Allow range: 0.375*FS~0.625*FS Span calibration gas (user calibration) Allow range:0.75*FS~1.25*FS Operating Temp. 5℃~45℃ Ambient Humidity 0% RH~95% RH (not condensing) Ambient Air Pressure 76kPa~116kPa

Because of special optics construction of Photo-acoustic trace gas measurement technology, acoustic signal assemble method and precise signal calculated process, photoacoustic technology became an effective way to assemble weak opto-acoustic signal and prevent background signal interference. It is an innovated technology special suitable for trace gas concentration measurement in complicated situation. Application: Industry Process control (Semiconductor, electric power, chemical industry, metallurgy, etc.) Environment pollution control Service and testing Waste gas analysis Process gas analysis Air quality control TOC value measurement Blast furnace gas detection Garbage landfill Tunnel gas detection Product Advantages: Professional trace gas measurement less than 5ppm Supports self-calibration by ambient air use acoustic signal for calculating concentration, less interference integrated infrared H2O detector, effective prevent humidity interference integrates pump and automatic valve control up to 3 sample points Equipped with an active carbon filter to prevent air pollution Sampling tube are stainless steel pipe, near to sample point each line has inline dust filter with exchangeable filter-element Effective prevent humidity interference: Integrated infra-red H2O detector for real-time calculation Effective prevent Temp. interference: Photoacoustic module heated to 50℃ Effective prevent other gas interference: Calculated with acoustic signal to gas concentration Measurement Gas List: Gas Measurement range Linearity error Accuracy Background gas NH3 Ammonia 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 NH3 Ammonia 0…1 g/m3 0.1% FS 0.1% FS Air or N2 C5H10 Cyclopentane 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 C3H6O Acetone 0…2000ppm 0.1% FS 0.1% FS Air or N2 C2H6O Ethyl Alcohol 0…2000ppm 0.1% FS 0.1% FS Air or N2 C3H8O Isopropyl Alcohol 0…1000ppm 0.1% FS 0.1% FS Air or N2 CH4O Methyl Alcohol 0…500ppm 0.1% FS 0.1% FS Air or N2 NF3 Cyclopentane 0…20ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 N2O Nitrous Oxide 0…500ppm 0.1% FS 0.1% FS Air or N2 C2Cl4 PERC 0…800ppm 0.1% FS 0.1% FS Air or N2 SO2F2 ProFume® 0…1 g/m3 0…1000ppm 1…150 g/m3 0.1% FS 0.1% FS Air or N2 CCl3F R11 0…500ppm 0.1% FS 0.1% FS Air or N2 C2Cl3F3 R113 0…50ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 C2F6 R116 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 CCl2F2 R12 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 C2HCl3F2 R122 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 C2HCl2F3 R123 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 CClF3 R13 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 CF4 R14 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 CHClF2 R22 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 CHF3 R23 0…150ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 C8H8 Styrene 0…50ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 SO2 Sulfur dioxide 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 SO2 Sulfur dioxide 0…1000ppm 0.1% FS 0.1% FS SF6 C8H20O4Si TEOS 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 C2HCl3F2 Toluene 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 C2HCl3 TRI 0…1000ppm 0.1% FS 0.1% FS Air or N2 CH3Br Methyl Bromide 0…2 g/m3 0.1% FS 0.1% FS N2 (only) For other gas please contact us for more information. Specification: Product Type SPTr-GAS® ANALYZER Detection Principle Photo acoustic Display LDL 0.1 ppm (typical), Depend on Range Response time Cycle time < 20s Detection Limit < 0.01 % FS ,Depend on Range Warm up Time heat up until 50°C (122°F), approximately 15 minutes at an ambient temperature of 20°C (68°F) Value Indication Digital indication (5.6” LCD) Unit: ppm, µmol/mol, mg/m3 Operation Handling Touch panel, 5.6” TFT Analog Output 4mA~20mA (normal operation) 2mA (in warm-up or status alarm) Analog Output Range Default is 4mA for lower range, and 20mA for upper range. User setable. Relay contact output Relay out quantity: x6 With relay out assignment for: x1 instrument error alarm x1 sample gas control valve relay signal for auto. cali. x1 auto. cali. zero gas supply control valve relay signal xN (N is channel quantity) auto. cali. span gas supply control valve relay signal xN (N is channel quantity) gas concentration upper/lower alarm Relay Property 1A contact (250V AC/2A, resistive load) Communication Standard RS232 (DB-9 female) RS485 with modbus protocol. Operating Voltage 98~242V AC, 50/60 Hz. Power consumption <125W Power inlet EN60320 C1 Fuse Fuse Current: 3A ,Blow Characteristic: Fast Acting Fuse Size Metric: 5mm x 20mm Case Protection Level IP41 (EN60529) Weight typical approx. 10kg (w/o package) approx. 19kg (w/ package) Gas Inlet Flow 0.4~0.8 L/min (Flow fluctuations ≤0.02 L/min) Inlet Gas Temp. 5~35 ℃ Inlet Gas Pressure 116kPa (max) Moisture in Gas • not condensing • inlet gas dew point:5℃±0.1℃ (This item is required when measure channel include NDIR SO2 and/or NO) Dust in gas flow 100µg/m³, ≤1µm Zero calibration gas 99.999Vol.% N2 (typical) 3th point(middle point) calibration gas range Allow range: 0.375*FS~0.625*FS Span calibration gas range (user calibration) Allow range: 0.75*FS~1.25*FS

SIGAS CGC-400 Marpol Emission gas monitoring system monitor CO2、SO2、NO、NO2、O2 of ship exhaust gas and the component of characteristic factor pollutants in fixed emitters. CGC-400 use NDIR and NDUV detection technology to detect different pollutant for various factor. CGC-400 can also fulfill different customer OEM requirement to add other components or function. Measurement Components: CO2 SO2 NO NO2 O2 Other pollutant components Product Advantages: Standard method: Products are Classification Society Type Certified High temperature probe sampling method: with automatic back blowing function; Whole process high temperature tracing method: ensure that the measured gas does not condense, the pipeline is not blocked, and the exhaust gas components are transmitted to the pretreatment system without loss, so as to ensure the authenticity and effectiveness of the measured values. Fast condensation method: the self-developed fast condenser is used to condense and remove water from flue gas, ensuring the minimum flue gas loss rate. Flexible expansion: the system can monitor CO2、SO2、NO、NO2、O2, and can also be customized according to the monitoring requirements of different customers; Multi point expansion: the system can monitor the exhaust gas concentration of two exhaust outlets, and can also customize the monitoring system for monitoring multiple outlets Integrated cabinet: with air conditioner Automation and intellectualization: it can realize the automatic unmanned operation of the whole system, automatic data storage and automatic report generation. Specification: System data Power supply AC 220V±10%,50Hz±1Hz,8KW(Including system equipment and air condition) Equipment Air (0.4-0.6)MPa, Gas consumption 15Nm3/h, Dew pooint:-20℃, oil free, water free Output signal DCA(4-20)mA; Operation(Auto,Manual), Maintaining, Malfunction; RS485, RS232, TCP/IP Environment Temp. 5℃~55℃ Environment Humidity ≤90% rel. Pressure 86-106kPa Measurement Items • CO2 • SO2 • NO • NO2 •O2 Sampling Sampling Probe + high Temp. Sampling process+Rapid condensation method Monitoring points 2 (can be expanded) Monitoring system Online gas analyzer Equipment Cabinet Cabinet accessories: online gas analyzer, cooler, system control unit, system analysis gas path unit; Control power supply: 220 VAC; Protection grade: IP55 Sampling Probe Protection level: IP65 Heating power: 400W Gas Measurement Online gas analyzer Measurement component and range: CO2 : (0~10) % (can be expanded) SO2 : (0~200) ppm (can be expanded) NO : (0~300) ppm (can be expanded) NO2 : (0~200) ppm (can be expanded) O2 : (0~25) % Measuring method: NDIR, NDUV, EC Linear error: ≤± 1% FS Repeatability: ≤± 1% FS Response time (T90): < 30 seconds Resolution: 0.1ppm, 0.01% Inlet gas flow: 0.4l/min-0.8l/min Display: LCD screen Operating language: Chinese and English, switchable Warm up time: ≤ 30min Output: 4-20mA, alarm signal, RS232, RS485,TCP/IP Installation in analysis cabinet

The SGS-200 furnace gas continuous analysis system has a special design for gas sampling probes, equipped with water cooling devices and automatic cleaning devices. The system is equipped with two gas sampling probes: the two probes can automatically cycle and switch, ensuring the stable operation of the smelting process furnace gas analysis system and continuous measurement and analysis of furnace gas composition. The SGS-200 gas online monitoring system consists of a sampling probe unit, a probe backwash unit, a preprocessing unit, and an instrument control unit. The sampling probe unit and probe backwash unit need to be installed on the flue, while the preprocessing unit and instrument control unit are integrated in the "analysis host cabinet". The pretreatment of the sample gas is equipped with filter accuracy which can reach 0.1μm. The sample gas with ultra-clean and stable flow rate meets the requirements of the high analytical accuracy and long-term reliability of the analytical gas system. This analysis system has its own independent power control and logic control functions, which control the detection, blowback, self-diagnosis and other functions of the measuring device, without the need for system control or manual operation outside the device. SGS-200 system has a system fault alarm contact output function, which can transmit signals to the DCS system. At the same time, the analysis system has analog or RS485 signal output.

SIGAS CGC-300 continuous emission monitoring system use UV detection technology to detect different pollutant for various factory according to local environment requirement. CGC-300 can also fulfill different customer OEM requirement to add other components or function. Application Industry environment protection control ( Semiconductor, electric power, chemical industry, metallurgy, etc.) Product Advantages: Standard method: the detection methods meet the requirements of national standards Whole process high temperature tracing method: ensure that the measured gas does not condense, the pipeline is not blocked, and the flue gas components are transmitted to the pretreatment system without loss, so as to ensure the authenticity and effectiveness of the measured values. Fast condensation method: the self-developed fast condenser is used to condense and remove water from flue gas, ensuring the minimum flue gas loss rate. Flexible expansion: the system can monitor sulfur dioxide, nitrogen oxides, particulate matter and the parameters of flue gas, and can also be customized according to the monitoring requirements of different customers; Automation and intellectualization: it can realize the automatic unmanned operation of the whole system, automatic data storage and automatic report generation. Specification: System data Power supply AC 220V±10%,50Hz±1Hz,8KW(Including system equipment and air condition) Equipment Air (0.4-0.6)MPa, Gas consumption 15Nm3/h, Dew pooint:-20℃, oil free, water free Output signal DCA(4-20)mA; Operation(Auto,Manual), Maintaining, Malfunction; RS485, RS232, TCP/IP Environment Temp. Indoor:15~35℃,Outdoor: -20~50℃ Environment Humidity ≤85% rel. Pressure 86-106kPa Measurement Items • SO2 • NOX • Particulate Matter • Flue gas temperature • Flue gas pressure • Flue gas flow • Flue gas humidity • Oxygen content of flue gas Sampling Sampling Probe + high Temp. Sampling process+Rapid condensation method Monitoring system Online gas analyzer Equipment Cabinet Cabinet accessories: online gas analyzer, cooler, system control unit, system analysis gas path unit; Control power supply: 220 VAC; Protection grade: IP55 Sampling Probe Protection level: IP65 Gas Measurement Online gas analyzer Measurement components: sulfur dioxide, nitrogen oxide, oxygen Measurement methods: UV detection technology, electrochemical detection technology Linear error: ≤± 1% FS Repeatability: ≤± 1% FS Response time (T90): < 30 seconds Resolution: 0.1ppm, 0.01% Inlet gas flow: 0.4l/min-0.8l/min Display: LCD screen Operating language: Chinese and English, switchable Warm up time: ≤ 30min Output: 4-20mA, alarm signal, RS232, RS485 Installation in analysis cabinet Temp., Pressure,Flow Temp.PressureFlowInstallation Measurement method: Platinum resistance; Range: 0~300℃; Accuracy: ±0.5%FSMeasurement method: Pressure Sensor; Range: -5KPa~+5KPa; Accuracy: ±0.5%FSMeasurement method: Pitot tube differential pressure; Range: 0~40m/s; Accuracy: ±1%Flanged mounting Particulate Matter Particulate analyzer Installation Measurement method: laser scattering; measuring range: 0 ~ 100mg / m3; accuracy: ± 1% Flanged mounting Humidity Humidity analyzer Installation Measurement method: resistance capacitance method; range: 0 ~ 40%; accuracy: ± 1% Installation in analysis cabinet

SIGAS CGC-400 Marpol Emission gas monitoring system monitor CO2、SO2、NO、NO2、O2 of ship exhaust gas and the component of characteristic factor pollutants in fixed emitters. CGC-400 use NDIR and NDUV detection technology to detect different pollutant for various factor. CGC-400 can also fulfill different customer OEM requirement to add other components or function. Measurement Components: CO2 SO2 NO NO2 O2 Other pollutant components Product Advantages: Standard method: Products are Classification Society Type Certified High temperature probe sampling method: with automatic back blowing function; Whole process high temperature tracing method: ensure that the measured gas does not condense, the pipeline is not blocked, and the exhaust gas components are transmitted to the pretreatment system without loss, so as to ensure the authenticity and effectiveness of the measured values. Fast condensation method: the self-developed fast condenser is used to condense and remove water from flue gas, ensuring the minimum flue gas loss rate. Flexible expansion: the system can monitor CO2、SO2、NO、NO2、O2, and can also be customized according to the monitoring requirements of different customers; Multi point expansion: the system can monitor the exhaust gas concentration of two exhaust outlets, and can also customize the monitoring system for monitoring multiple outlets Integrated cabinet: with air conditioner Automation and intellectualization: it can realize the automatic unmanned operation of the whole system, automatic data storage and automatic report generation. Specification: System data Power supply AC 220V±10%,50Hz±1Hz,8KW(Including system equipment and air condition) Equipment Air (0.4-0.6)MPa, Gas consumption 15Nm3/h, Dew pooint:-20℃, oil free, water free Output signal DCA(4-20)mA; Operation(Auto,Manual), Maintaining, Malfunction; RS485, RS232, TCP/IP Environment Temp. 5℃~55℃ Environment Humidity ≤90% rel. Pressure 86-106kPa Measurement Items • CO2 • SO2 • NO • NO2 •O2 Sampling Sampling Probe + high Temp. Sampling process+Rapid condensation method Monitoring points 2 (can be expanded) Monitoring system Online gas analyzer Equipment Cabinet Cabinet accessories: online gas analyzer, cooler, system control unit, system analysis gas path unit; Control power supply: 220 VAC; Protection grade: IP55 Sampling Probe Protection level: IP65 Heating power: 400W Gas Measurement Online gas analyzer Measurement component and range: CO2 : (0~10) % (can be expanded) SO2 : (0~200) ppm (can be expanded) NO : (0~300) ppm (can be expanded) NO2 : (0~200) ppm (can be expanded) O2 : (0~25) % Measuring method: NDIR, NDUV, EC Linear error: ≤± 1% FS Repeatability: ≤± 1% FS Response time (T90): < 30 seconds Resolution: 0.1ppm, 0.01% Inlet gas flow: 0.4l/min-0.8l/min Display: LCD screen Operating language: Chinese and English, switchable Warm up time: ≤ 30min Output: 4-20mA, alarm signal, RS232, RS485,TCP/IP Installation in analysis cabinet

SIGAS CGC-400 Marpol Emission gas monitoring system monitor CO2、SO2、NO、NO2、O2 of ship exhaust gas and the component of characteristic factor pollutants in fixed emitters. CGC-400 use NDIR and NDUV detection technology to detect different pollutant for various factor. CGC-400 can also fulfill different customer OEM requirement to add other components or function. Measurement Components: CO2 SO2 NO NO2 O2 Other pollutant components Product Advantages: Standard method: Products are Classification Society Type Certified High temperature probe sampling method: with automatic back blowing function; Whole process high temperature tracing method: ensure that the measured gas does not condense, the pipeline is not blocked, and the exhaust gas components are transmitted to the pretreatment system without loss, so as to ensure the authenticity and effectiveness of the measured values. Fast condensation method: the self-developed fast condenser is used to condense and remove water from flue gas, ensuring the minimum flue gas loss rate. Flexible expansion: the system can monitor CO2、SO2、NO、NO2、O2, and can also be customized according to the monitoring requirements of different customers; Multi point expansion: the system can monitor the exhaust gas concentration of two exhaust outlets, and can also customize the monitoring system for monitoring multiple outlets Integrated cabinet: with air conditioner Automation and intellectualization: it can realize the automatic unmanned operation of the whole system, automatic data storage and automatic report generation. Specification: System data Power supply AC 220V±10%,50Hz±1Hz,8KW(Including system equipment and air condition) Equipment Air (0.4-0.6)MPa, Gas consumption 15Nm3/h, Dew pooint:-20℃, oil free, water free Output signal DCA(4-20)mA; Operation(Auto,Manual), Maintaining, Malfunction; RS485, RS232, TCP/IP Environment Temp. 5℃~55℃ Environment Humidity ≤90% rel. Pressure 86-106kPa Measurement Items • CO2 • SO2 • NO • NO2 •O2 Sampling Sampling Probe + high Temp. Sampling process+Rapid condensation method Monitoring points 2 (can be expanded) Monitoring system Online gas analyzer Equipment Cabinet Cabinet accessories: online gas analyzer, cooler, system control unit, system analysis gas path unit; Control power supply: 220 VAC; Protection grade: IP55 Sampling Probe Protection level: IP65 Heating power: 400W Gas Measurement Online gas analyzer Measurement component and range: CO2 : (0~10) % (can be expanded) SO2 : (0~200) ppm (can be expanded) NO : (0~300) ppm (can be expanded) NO2 : (0~200) ppm (can be expanded) O2 : (0~25) % Measuring method: NDIR, NDUV, EC Linear error: ≤± 1% FS Repeatability: ≤± 1% FS Response time (T90): < 30 seconds Resolution: 0.1ppm, 0.01% Inlet gas flow: 0.4l/min-0.8l/min Display: LCD screen Operating language: Chinese and English, switchable Warm up time: ≤ 30min Output: 4-20mA, alarm signal, RS232, RS485,TCP/IP Installation in analysis cabinet

SIGAS CGC-300 continuous emission monitoring system use UV detection technology to detect different pollutant for various factory according to local environment requirement. CGC-300 can also fulfill different customer OEM requirement to add other components or function. Application Industry environment protection control ( Semiconductor, electric power, chemical industry, metallurgy, etc.) Product Advantages: Standard method: the detection methods meet the requirements of national standards Whole process high temperature tracing method: ensure that the measured gas does not condense, the pipeline is not blocked, and the flue gas components are transmitted to the pretreatment system without loss, so as to ensure the authenticity and effectiveness of the measured values. Fast condensation method: the self-developed fast condenser is used to condense and remove water from flue gas, ensuring the minimum flue gas loss rate. Flexible expansion: the system can monitor sulfur dioxide, nitrogen oxides, particulate matter and the parameters of flue gas, and can also be customized according to the monitoring requirements of different customers; Automation and intellectualization: it can realize the automatic unmanned operation of the whole system, automatic data storage and automatic report generation. Specification: System data Power supply AC 220V±10%,50Hz±1Hz,8KW(Including system equipment and air condition) Equipment Air (0.4-0.6)MPa, Gas consumption 15Nm3/h, Dew pooint:-20℃, oil free, water free Output signal DCA(4-20)mA; Operation(Auto,Manual), Maintaining, Malfunction; RS485, RS232, TCP/IP Environment Temp. Indoor:15~35℃,Outdoor: -20~50℃ Environment Humidity ≤85% rel. Pressure 86-106kPa Measurement Items • SO2 • NOX • Particulate Matter • Flue gas temperature • Flue gas pressure • Flue gas flow • Flue gas humidity • Oxygen content of flue gas Sampling Sampling Probe + high Temp. Sampling process+Rapid condensation method Monitoring system Online gas analyzer Equipment Cabinet Cabinet accessories: online gas analyzer, cooler, system control unit, system analysis gas path unit; Control power supply: 220 VAC; Protection grade: IP55 Sampling Probe Protection level: IP65 Gas Measurement Online gas analyzer Measurement components: sulfur dioxide, nitrogen oxide, oxygen Measurement methods: UV detection technology, electrochemical detection technology Linear error: ≤± 1% FS Repeatability: ≤± 1% FS Response time (T90): < 30 seconds Resolution: 0.1ppm, 0.01% Inlet gas flow: 0.4l/min-0.8l/min Display: LCD screen Operating language: Chinese and English, switchable Warm up time: ≤ 30min Output: 4-20mA, alarm signal, RS232, RS485 Installation in analysis cabinet Temp., Pressure,Flow Temp.PressureFlowInstallation Measurement method: Platinum resistance; Range: 0~300℃; Accuracy: ±0.5%FSMeasurement method: Pressure Sensor; Range: -5KPa~+5KPa; Accuracy: ±0.5%FSMeasurement method: Pitot tube differential pressure; Range: 0~40m/s; Accuracy: ±1%Flanged mounting Particulate Matter Particulate analyzer Installation Measurement method: laser scattering; measuring range: 0 ~ 100mg / m3; accuracy: ± 1% Flanged mounting Humidity Humidity analyzer Installation Measurement method: resistance capacitance method; range: 0 ~ 40%; accuracy: ± 1% Installation in analysis cabinet

The VOCs Online measurement system CGC-100 use on-line gas chromatography with FID detector, to detect different pollutant for various factory according to local environment requirement. CGC-100 can also fulfill different customer OEM requirement to add other components or function. CH4, THC, NMHC BETX such as: benzene, methyl-benzene, xylene; Other characteristic Volatile organic compounds in emission sources (including odorous organic compounds) SIGAS CGC-100 VOCs Online measurement system equipped with a high-end process chromatograph, allowing manual and automatic sampling and analysis, equipped with FID hydrogen flame ion detector, showing good linearity in detecting combustible hydrocarbons. Application ▪ Industry environment protection control ( Semiconductor, electric power, chemical industry, metallurgy, etc.) Product Advantages: Standard method: FID gas chromatography (GC) is an internationally recognized standard method for VOCs detection; full process high temperature tracing method: to ensure that the measured gas does not condense, no condensation, pipeline is not blocked, and VOC components are transmitted to the analyzer for measurement without loss, ensuring the authenticity and effectiveness of the measured values. Flexible expansion: The system can monitor total hydrocarbon, non-methane total hydrocarbon, benzene series, odor and other hundreds of organic waste gas, can be customized according to different customer monitoring needs with superior scalability; Automation and intelligence: automatic unmanned operation of the whole system can be realized; Specification: System data Power supply AC 220V±10%,50Hz±1Hz,8KW (Including system equipment and air condition) Equipment Air (0.4-0.6)MPa, Gas consumption 15Nm3/h, Dew pooint: -20℃, oil free, water free Output signal DCA(4-20)mA; Operation(Auto,Manual), Maintaining, Malfunction; RS485, RS232, TCP/IP Environment Temp. Indoor 15~35℃,Outdoor -20~50℃ Environment Humidity ≤85% rel. Pressure 86-106kPa Measurement Items NMHC, benzene, methyl-benzene, xylene, Temp., Pressure, Flow. Sampling Sampling Probe + high Temp. Sampling process Monitoring system on-line gas chromatography Equipment Cabinet GC, system control item, gas pipe item, power supply:220VAC, Protection level:IP55 Sampling Probe Protection level: IP65 Gas Measurement GC Detector: FID Detection Limit < 0.1mg/m3 Measurement range 0-50/100/200/1000/5000mg/Nm3 adjustable RSD ≤ 3% Linearity ≤5% F.S Indication error: related error <10% Measurement cycle Hydrogen generator Nitrogen Standard gas < 2min Hydrogen purity: 99.999%; Hydrogen flow: 20ml/min; Working pressure: 0.3Mpa; Nitrogen purity: 99.999%; Nitrogen flow: 45ml/min; Working pressure: 0-0.4Mpa; Standard gas: C3H8+CH4+N2, benzene+ methyl-benzene+xylene+N2; Standard gas flow: 30ml/min; Working pressure: 0.2Mpa; Temp., Pressure,Flow Temp. Pressure Flow Installation Measurement method: Platinum resistance; Range: 0~300℃; Accuracy: ±0.5%FS Measurement method: Pressure Sensor; Range: -5KPa~+5KPa; Accuracy: ±0.5%FS Measurement method: Pitot tube differential pressure; Range: 0~40m/s; Accuracy: ±1% Flanged mounting

SPTr-GAS® SYSTEM 300 as photoacoustic measurement platform use mainly the photoacoustic analysis technology, equipped with automatic gas control and large touch screen. The system operation is simple, with more than 4 gases and different ranges measurement, the system is multi-functional, intelligent and qualified for high precise laboratories use. As a platform for fumigation gas analysis and verification, the platform has the characteristics of high precision, sensitivity and good linearity, it can evaluate the gas concentration of bromomethane, sulfuryl fluoride, carbon dioxide and other fumigants. It can also be used as a benchmark analysis device to test and evaluate instruments and equipment commonly used in the industry such as fumigation gas alarms, handheld detectors, and portable detectors. Specification: Measurement Principle Photoacoustic spectrum (carbon dioxide is detected by infrared method, fumigation gas leakage alarm device is detected by photoionization, infrared and electrochemical methods) Measured Gases Bromomethane, sulfuryl fluoride, carbon dioxide, phosphine Measured Range CH3Br:0-250 g/m3,Accuracy 0.1 g/m3; CH3Br:0-200 ppm,Accuracy 0.1 ppm; SO2F2:0-200 g/m3,Accuracy 0.1 g/m3; SO2F2:0-220 ppm,Accuracy 0.1 ppm; CO2:0-5000ppm, 0-20%, 0-100%;Accuracy ±2%F.S; Resolution 0.01 g/m3 or 0.1ppm; Warum-up Time ≤15min ResponseTime The response time for each detection cycle is ≤20s Calibration Function Zero point calibration, third point calibration and span calibration, automatic and manual calibration Self-Check The instrument has a self-test function, when an error occurs, the error signal code is given Signal Output 4…20mA,RS232or RS485

The SIGAS CCS-100 Testing Workstation for core components in steady gas environment process purpose: To build a monitoring station with automatic opening and closing doors, to accommodate the required number of gas core components in a closed box environment, place them in batch loading trays, maintain a closed environment of process gas concentration, and wait for the core components to complete the process detection purpose in a closed gas environment, Automatically empty the gas inside the box and move the core components out of the box. The equipment runs automatically and completes the entire process. At the same time, the closed monitoring station has a certain degree of airtightness to ensure the safety of the testing process. In case of gas leakage, emergency plans should be immediately activated. SIGAS CCS-100 Testing workstation can be widely used in the production process such as, power-train testing, interior/exterior trim parts testing, new energy battery thermal runaway module performance monitoring and other industrial process testing. Meanwhile, CCS-100 can also be flexibly customized based on different technical requirements and product characteristics. It is available in both full-/semi-automatic and manual modes, making it suitable for various manufacturing application test scenarios such as engines and their components, new energy battery modules, and semiconductor production processes. CCS-100 can also provide comprehensive support for product quality control and performance inspection, as well as offer complete adaptive monitoring programs for industrial manufacturing processes in various fields. Automotive industry Semiconductor New energy/Battery Module Testing process for all kinds of core sensor manufacturing Product Advantages: Tests the performance of core components in a closed gas environment Automatic intake and exhaust (including interface, solenoid valve, pipe, etc.), automatic control of intake and exhaust flow. one-key automatic opening and closing door, can also be controlled by program; The automatic opening and closing of the box door does not affect the interference when the clamping hand is grasped and placed. Automatically selects the defective components and puts them into the designated defective tray, automatically replenishes the samples, and automatically collects the relevant data of the core components to be tested. A leakage detector is placed outside the monitoring station container. When gas leakage is detected, an audible and visual alarm is generated and an emergency plan is activated. The man-machine interface display of the monitoring station can realize manual and automatic control of the equipment, warning and alarm error notification, etc. The interface is simple and friendly, and the operation is easy to understand. Specification: system Test the performance of core components in a closed gas environment Gas concentration CO gas concentration atmosphere 100ppm/400ppm Air supply CO, concentration 100% Test time The duration of a single test is 60 minutes Sealed tightly No gas leakage is allowed, in line with process requirements Supply voltage AC220V±10% (or 380V factory voltage) at 50±1Hz Ambient temperature 10~35℃ Ambient humidity ≤95%RH atmospheric pressure 76kPa~116kPa Air supply requirements Oil-free and water-free compressed air (>0.7MPa), negative pressure (suction), medium gas source (concentration according to process requirements) Device communication RS232/RS485, etc

Because of special optics construction of Photo-acoustic trace gas measurement technology, acoustic signal assemble method and precise signal calculated process, photoacoustic technology became an effective way to assemble weak opto-acoustic signal and prevent background signal interference. It is an innovated technology special suitable for trace gas concentration measurement in complicated situation. Application: Industry Process control (Semiconductor, electric power, chemical industry, metallurgy, etc.) Environment pollution control Service and testing Waste gas analysis Process gas analysis Air quality control TOC value measurement Blast furnace gas detection Garbage landfill Tunnel gas detection Product Advantages: Professional trace gas measurement less than 5ppm Supports self-calibration by ambient air use acoustic signal for calculating concentration, less interference integrated infrared H2O detector, effective prevent humidity interference integrates pump and automatic valve control up to 3 sample points Equipped with an active carbon filter to prevent air pollution Sampling tube are stainless steel pipe, near to sample point each line has inline dust filter with exchangeable filter-element Effective prevent humidity interference: Integrated infra-red H2O detector for real-time calculation Effective prevent Temp. interference: Photoacoustic module heated to 50℃ Effective prevent other gas interference: Calculated with acoustic signal to gas concentration Measurement Gas List: Gas Measurement range Linearity error Accuracy Background gas NH3 Ammonia 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 NH3 Ammonia 0…1 g/m3 0.1% FS 0.1% FS Air or N2 C5H10 Cyclopentane 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 C3H6O Acetone 0…2000ppm 0.1% FS 0.1% FS Air or N2 C2H6O Ethyl Alcohol 0…2000ppm 0.1% FS 0.1% FS Air or N2 C3H8O Isopropyl Alcohol 0…1000ppm 0.1% FS 0.1% FS Air or N2 CH4O Methyl Alcohol 0…500ppm 0.1% FS 0.1% FS Air or N2 NF3 Cyclopentane 0…20ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 N2O Nitrous Oxide 0…500ppm 0.1% FS 0.1% FS Air or N2 C2Cl4 PERC 0…800ppm 0.1% FS 0.1% FS Air or N2 SO2F2 ProFume® 0…1 g/m3 0…1000ppm 1…150 g/m3 0.1% FS 0.1% FS Air or N2 CCl3F R11 0…500ppm 0.1% FS 0.1% FS Air or N2 C2Cl3F3 R113 0…50ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 C2F6 R116 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 CCl2F2 R12 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 C2HCl3F2 R122 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 C2HCl2F3 R123 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 CClF3 R13 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 CF4 R14 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 CHClF2 R22 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 CHF3 R23 0…150ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 C8H8 Styrene 0…50ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 SO2 Sulfur dioxide 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 SO2 Sulfur dioxide 0…1000ppm 0.1% FS 0.1% FS SF6 C8H20O4Si TEOS 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 C2HCl3F2 Toluene 0…100ppm 0.5ppm / 0.1% FS 0.1ppm / 0.1% FS Air or N2 C2HCl3 TRI 0…1000ppm 0.1% FS 0.1% FS Air or N2 CH3Br Methyl Bromide 0…2 g/m3 0.1% FS 0.1% FS N2 (only) For other gas please contact us for more information. Specification: Product Type SPTr-GAS® ANALYZER Detection Principle Photo acoustic Display LDL 0.1 ppm (typical), Depend on Range Response time Cycle time < 20s Detection Limit < 0.01 % FS ,Depend on Range Warm up Time heat up until 50°C (122°F), approximately 15 minutes at an ambient temperature of 20°C (68°F) Value Indication Digital indication (5.6” LCD) Unit: ppm, µmol/mol, mg/m3 Operation Handling Touch panel, 5.6” TFT Analog Output 4mA~20mA (normal operation) 2mA (in warm-up or status alarm) Analog Output Range Default is 4mA for lower range, and 20mA for upper range. User setable. Relay contact output Relay out quantity: x6 With relay out assignment for: x1 instrument error alarm x1 sample gas control valve relay signal for auto. cali. x1 auto. cali. zero gas supply control valve relay signal xN (N is channel quantity) auto. cali. span gas supply control valve relay signal xN (N is channel quantity) gas concentration upper/lower alarm Relay Property 1A contact (250V AC/2A, resistive load) Communication Standard RS232 (DB-9 female) RS485 with modbus protocol. Operating Voltage 98~242V AC, 50/60 Hz. Power consumption <125W Power inlet EN60320 C1 Fuse Fuse Current: 3A ,Blow Characteristic: Fast Acting Fuse Size Metric: 5mm x 20mm Case Protection Level IP41 (EN60529) Weight typical approx. 10kg (w/o package) approx. 19kg (w/ package) Gas Inlet Flow 0.4~0.8 L/min (Flow fluctuations ≤0.02 L/min) Inlet Gas Temp. 5~35 ℃ Inlet Gas Pressure 116kPa (max) Moisture in Gas • not condensing • inlet gas dew point:5℃±0.1℃ (This item is required when measure channel include NDIR SO2 and/or NO) Dust in gas flow 100µg/m³, ≤1µm Zero calibration gas 99.999Vol.% N2 (typical) 3th point(middle point) calibration gas range Allow range: 0.375*FS~0.625*FS Span calibration gas range (user calibration) Allow range: 0.75*FS~1.25*FS

SPTr-GAS® SYSTEM 300 as photoacoustic measurement platform use mainly the photoacoustic analysis technology, equipped with automatic gas control and large touch screen. The system operation is simple, with more than 4 gases and different ranges measurement, the system is multi-functional, intelligent and qualified for high precise laboratories use. As a platform for fumigation gas analysis and verification, the platform has the characteristics of high precision, sensitivity and good linearity, it can evaluate the gas concentration of bromomethane, sulfuryl fluoride, carbon dioxide and other fumigants. It can also be used as a benchmark analysis device to test and evaluate instruments and equipment commonly used in the industry such as fumigation gas alarms, handheld detectors, and portable detectors. Specification: Measurement Principle Photoacoustic spectrum (carbon dioxide is detected by infrared method, fumigation gas leakage alarm device is detected by photoionization, infrared and electrochemical methods) Measured Gases Bromomethane, sulfuryl fluoride, carbon dioxide, phosphine Measured Range CH3Br:0-250 g/m3,Accuracy 0.1 g/m3; CH3Br:0-200 ppm,Accuracy 0.1 ppm; SO2F2:0-200 g/m3,Accuracy 0.1 g/m3; SO2F2:0-220 ppm,Accuracy 0.1 ppm; CO2:0-5000ppm, 0-20%, 0-100%;Accuracy ±2%F.S; Resolution 0.01 g/m3 or 0.1ppm; Warum-up Time ≤15min ResponseTime The response time for each detection cycle is ≤20s Calibration Function Zero point calibration, third point calibration and span calibration, automatic and manual calibration Self-Check The instrument has a self-test function, when an error occurs, the error signal code is given Signal Output 4…20mA,RS232or RS485

SPGAS® PORT mini is SIGAS comprehensive portable analzyer type, which used for Multi-Gas concentration measurement, can equipped with all kind of gas sensors according to customer requirement with alarm output and real time concentration display. The device is small and convenient, can be used for industry routing inspection, toxic gas measurement and so on. Application: Industry Process control ( Semiconductor, electric power, chemical industry, metallurgy, etc.) Environment pollution control Service and testing Waste gas analysis Process gas analysis Air quality control TOC value measurement Blast furnace gas detection Garbage landfill Tunnel gas detection Fumigation Product Advantages: Portable design, Internally integrated high capacity battery, used for more than 8 hours working time, suitable for all kind of motive gas measurement requirement. can flexible install sensors according to customer requirement. integrated low noisy pump, for high stable sampler gas. Equipped with zero calibration button, for adjust the automatic calibration after turn on, freely according to customer need. Equipped with simply “Start”, “Stop”, “Blow back” function all on the surface of device. Simply display with clear design (Date, battery, all status, concentration, alarm, calibration and so on.) Flexible gas connection, 1/8"NPT connector suitable with all kind of gas joint。 internal filter protection, for protect high accuracy sensor with pollution. Back side with RS232 connection, charging and display for charging and USB connector. Measurement data can be stored on USB, store cycle adjust by customer Concentration item and alarm can be set by customer. Standard type can show 1-3 channels Standard software can be used for store data with excel or TXT version, also with full function adjustment. Specification: Measurement channel 3 Channel - Measurement Gas type - Measurement range - Measurement error Response time General: <30s (t90 @36 L/h with stable flow) Display 4.9” Display Operation Buttons Display resolution General: - Item is g/m3: 0.1g/m3 - Item is %: 0.01% - Item is µmol/mol: 0.1 µmol/mol Communication Standard: RS232 (DB-9 Female) communication protocol please refer Appendix. Optional: Bluetooth V2.0 2.4GHz(wireless communication distance ~10m in open space) BQB, FCC certified USB for USB disk data storage use, recommended USB disk volume: 16GB (FAT32) Battery Li-Battery Pack Battery Time ≥8h @25℃ Charging time From 5% to 90% need around 5h @25℃ Power Suply Input (100~260)VAC, (47~63) Hz Output 24VDC (0~6)A Safety regulation: UL62368-1, CSA C22.2 No.62368-1, TUV EN62368-1, CCC GB4943.1 (Only the original charging adapter is allowed!) Heating time NDIR ≤15min Cold start @25℃ EC ≤10min Cold start @25℃ Gas Sampler Sampled by build in gas pump(3±0.5L/min) Gas Inlet requirement Inlet Gas Temp: (5~40) ℃ Inlet Gas particulates : <100µg/m³, ≤1µm, External sampling and filtering is needed, for some types of sensors, water vapor may cause interference. Please contact the manufacturer's technical support for details。 Working Temp. Working: 5~40℃ Charging: 0~45℃ Working Humidity 0% RH~95% RH (non-condensing) Working Pressure 76kPa~116kPa

The novel patented stabilization of the High efficiency Radionuclide-identifier RadXplore-ident is based on the measurement of the quantum photoelectric effect. It requires no built-in source or LED and instantly and automatically compensates for any gain variations due to hysteresis and temperature changes. RadXplore-ident, in the development of the device, which is powered by a Li-ion battery powered device, great emphasis was placed on comfortable handling as well as a high degree of user-friendliness. The result is a housing shape and weight that makes the RadXplore-ident highly ergonomic and unique: compact and operable with on hand. This is because, for the first time, it has been possible to combine a 2”x1” BGO (bismuth germanate) detector with high-precision, high speed digital electronics in a ergonomic, light-weight and waterproof aluminum housing that can be operated with on hand. The RadXplore-ident convinces in use on land, on water and even under water up to 10 meters diving depth. With the highest precision, the RadXplore-ident thus provides consistent performance in all conditions and environments, reducing false alarms and shortening decision-making processes in the field. Especially for missions with unknown risks, the wide measurement range (10 keVee to 1000 MeVee) as well as the dose rate measurement is a convincing advantage. The sophisticated analog and digital electronics make it possible to measure a wide gamma dose rate range and neutrons with only one BGO crystal. Low radiation levels can be detected earlier, faster and with higher accuracy than with comparable handheld instruments. Stronger radiation sources are analyzed and identified even at high input rates. With the Easy-Finder function, radiation sources can be found, located and then quickly identified. For example, a radiation source with an activity of 37 kBq Cs-137 is identified within 3 seconds. Specification: Technology Radionuclide identification device Measurement range Detecting gamma γ rays emitted from natural and artificial sources β、 Neutrons and cosmic radiation. Identify special nuclear materials, industrial, medical, and natural radiation sources. Measure X-ray and gamma γ exposure rates or environmental dose equivalents. BGO detector Working range Gamma and thermal neutron detection Material Bi4Ge3O12 (Gd2O3) Size 51 Ø x 25 mm3 (2“ x 1”) PHR 9.0 ±1.5 % @ 662 keV Energy range 10 keVee – 1000 MeVee (total)10 keV – 10 MeV (gamma γ rays and X-ray)10 MeVee – 1000 MeVee (cosmic radiation, μ mesotron, charged particle) Total dose rate range (cesium-137) 10 nSv/h - 500 mSv/h (1 μrem/h - 50 rem/h) ±30 % Dose rate range ID mode (cesium-137) 10 nSv/h - 200 μSv/h (1 μrem/h - 20 mrem/h) Dose rate range current variance mode (cesium-137) 200 μSv/h - 500 mSv/h (0,02 rem/h - 50 rem/h) Dose rate overload range (cesium-137) > 500 mSv/h (50 rem/h) Maximum input count rate in ID mode 100 万 cps (Cesium-137) Gamma sensitivity 1,850 cps/μSv/h (Cesium-137) neutron According to ANSI N42.34 neutron sensitivity ~5 cps/nv Performance Power on time The operation can be completed in less than a minute Recognition Time Identify 1 µ Ci cesium-137 within 3 seconds (5 centimeters from the crystal center) Linearization Real time linearization of gamma energy User interface update frequency 0.5 s Nuclide library > 70 nuclides (exceeding IEC 62327, ANSI N42.34)

Application: Fire and civil defense Non-destructive testing Nuclear Medicine Industrial Testing Research and Education Product Advantages: Dosemeter for measuring gamma and X-ray radiation for the measurand Hp(10) (deep personal dose) Detector: Energy-compensated Geiger-Müller counter tube Switchable acoustic single pulse detection Menu-driven operator guidance Storage of the dose value and the set parameters even when the battery is changed Four factory preset dose warning thresholds Factory preset dose rate warning threshold Visual and audible warning High reliability due to constant self-monitoring Small, handy housing, well decontaminable, protection class IP54 Operating time with one set of batteries in ambient radiation approx. 1 month in 24 h operation and 3 months in 8 h operation Audible battery warning Mounting clip and device bag included Specification: Measuring range 1 μSv – 10 Sv Measured variable Hp (10) (deep personal dose) Radiation type Gamma and X-ray radiation Energy sector 55 keV – 1.3 MeV

Application: Fire and civil defence Non-destructive testing Nuclear Medicine Industrial Testing Research and Education Product Advantages: High-performance, mobile contamination monitor with thin-layer plastic scintillation detector (complete elimination of gas-filled or gas-purged detectors). A detector can be used to make α-, β- and γ-sensitive measurements, and the measurement system automatically detects whether alpha radiation is present Possibility of simultaneous or selective measurement of α- and β-/γ-contaminations User-friendly user interface (operation via 5 function keys) Settings and measured value parameters protected by password Integrated measurement data storage, optional software for reading and processing the measurement data Connection option for various external probes, e.g. for dose rate measurement Automatic detection of the probes Optional stationary use in wall station with power supply In case of mechanical destruction of the detector foil, the repair can be carried out inexpensively by the user himself (no costly detector repair in the manufacturer’s factory necessary as with the xenon detector) Avoidance of high operating costs for gas flushing Special versions: CoMo-170 ZS and F: adapted to the tasks of the civil defense and the fire department CoMo-170 DL: with additional GM counter tube integrated into the front face for measuring the dose rate CoMo-170/-300 G: for pure gamma measurements Specification: Detector type Thin Film Plastic Scintillation Detector with ZnS Coating Detector size 170 cm² Display ranges α-channel up to 5,000 Ip/s β-γ-channel up to 50,000 Ip/s Measuring ranges α-channel up to 2,500 Ip/s β-γ-channel up to 20,000 Ip/s Zero effect α-channel approx. 0.1 Ip/s β-γ-channel approx. 15 – 20 Ip/s Dimensions approx. 280 × 125 × 135 mm Weight (incl. batteries) approx. 800 g Protection class IP54 (Protected against splashing water)

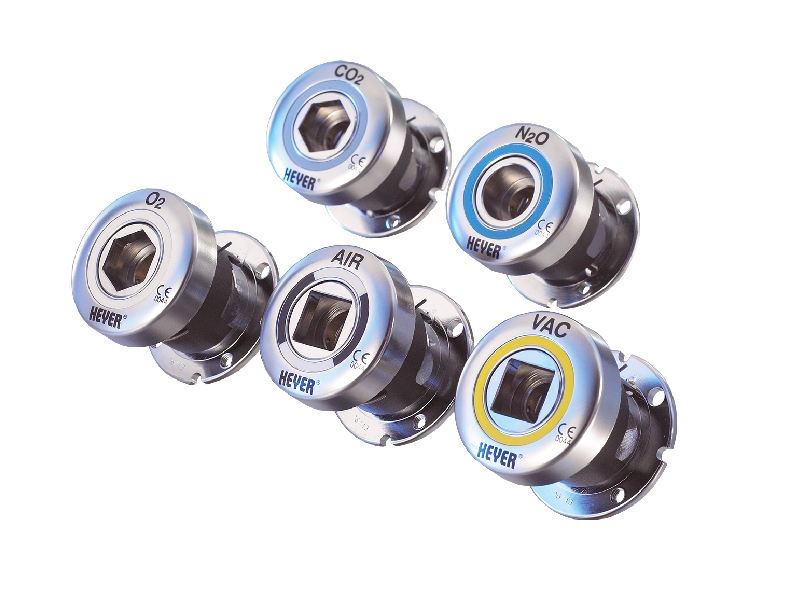

The HEYER Medical Gas Outlets is designed that the user can establish a secure connection between the plug and the extraction point. Product Advantages: Medical Gas Outlets are manufactured in strict accordance with DIN EN ISO 9170-1 and DIN 13620-2/2004 uses ISO32 set color ring to identify gas, and meets the requirements of GB50751-2012 specification Medical Gas Outlets is made of metal material to distinguish gas by different shapes Base, spool, valve body, etc., are forged with brass in one molding Internal check valve and safety valve separation design The Medical Gas Outlets has the on/off function to disconnect the gas supply without pulling out the plug to avoid plug contamination can be independent maintenance without cut off the gas more than 50,000 safe insertions and removals Specification: Probe connection acc. to DIN 13260-2 Valve socket H = 27 mm Installation depth 65 mm Copper pipe Ø 8 mm Other probe codifications and gas types upon request

The HEYER switching device comes in multiple models and is suitable for different application scenarios, such as small hospital oxygen station gas supply sources, large hospital oxygen station backup gas supply sources, special gas supply sources for operating rooms, and special gas supply sources for reproductive centers. Product Advantages: Fully automatic switching between main and backup air sources is achieved through a high-performance switching valve The maximum flow rate can reach 160m3/h, and the system status is displayed in real-time through an LCD display screen The internal first and second level pressure reduction adopts a one in use and one backup design, which can be maintained with gas Configure the third emergency access port to NIST gas source, which can still automatically switch after a power outage to ensure continuous gas supply Real time monitoring of the pressure of the manifold exhaust cylinder and the output pressure of the pipeline, and implementing sound and light alarms for high and low pressure states. The alarm status is transmitted to the central monitoring system platform through remote communication modules Display online the inventory of left and right gas cylinder groups, the pressure of the third gas source, the working pressure of the system, and the outlet pressure of the pipeline The working pressure of the system is the pressure after first level pressure reduction, and the outlet pressure of the pipeline is the output pressure that enters the pipeline network after second level pressure stabilization Implement high and low pressure audible and visual alarms for various pressure states, and remotely transmit the alarm signals to the central monitoring system platform Alarm signals are transmitted in real-time to the central monitoring system platform through remote communication modules Real time display of the switching valve position and the air source being used Real time detection of gas flow rate, and reading of gas flow rate through the right mute button The system automatically records the date and time of gas cylinder replacement Real time recording of system faults and tracing through calling device fault logs The gas consumption of gas cylinders, pressure status after pressure reduction, output pressure status, gas flow rate, gas source activation status, ambient temperature, and internal lighting of the equipment can be set as needed through the system menu Specification: AGS 35-50 Switching device (standard) O2/N2O/CO2/N2/Air Pneumatic switching principle (differential pressure type), the maximum flow of 50m3/h AGS 80 D Switching device (high configuration) O2/N2O/CO2/N2/Air Electromagnetic switching principle, flow 80-160m3/h AGS 80 P Switching device (standard) O2/N2O/CO2/N2/Air Pneumatic switching principle (differential pressure type), flow 80-160m3/h AGS 35-50 Switching device (standard) O2/N2O/CO2/N2/Air Pneumatic switching principle (differential pressure type), the maximum flow of 50m3/h For other parameters or type requirements, contact the manufacturer

Ambulances can be divided into three types from the use of function, which are: transport type (transfer type), monitoring type and negative pressure type. The transfer ambulance is the simplest of the three types of ambulances, mainly responsible for the transfer of patients. It can be converted into a monitoring ambulance or a negative pressure ambulance by adding medical equipment and installing a negative pressure system. HEYER has a series of ambulance products, can be installed in the ambulance, converted into a monitoring or negative pressure ambulance, can achieve in-car first aid. Product Advantages: Develop and manufacture high quality medical gas supply equipment and accessories Easy to use, can rescue patients in the car, to achieve the first time emergency rescue. equipped with sound and light alarm system The dedicated oxygen decompression panel in the ambulance makes it easy to supply oxygen inside the vehicle Specification: Pressure relief panel composition Pressure sensor Oxygen pressure reducing valve 200bar-5bar Solenoid valve 24v, bypass, manual switching device Cylinders are automatically switched one by one Sound and light alarm system It can display the digital status of the pressure reduction panel and issue sound and light alarm when the pressure is abnormal Oxygen humidification unit for ambulances Concealed humidifier 1-4 channels Single or four channels at the same time Flow gear adjustment 1-9 0-15L/min (customizable)

SIGAS products can be widely used in semiconductor processing, new energy, petroleum, chemical, metallurgy, mining, pharmaceutical, packaging industry and so on.

SIGAS products can be widely used in semiconductor processing, new energy, petroleum, chemical, metallurgy, mining, pharmaceutical, packaging industry and so on.

Products Category

Products Type Industry / Environment / Inspection / Medical / Marine / nuclear

Invention Patent / Application Patent

Country Of Cooperation

SIGAS is life in LinkedIN, WeChat, Facebook, Stay up-to-date with us, on the latest news, events and upcoming exhibitions.

18

2025.01Exhibition Name Date Country Company/Exhibitor InterAqua 2025.01.29-31 Japan IR System smartGAS Distributor (Japan) Photonics West 2025.01.28-30 US EOC smartGAS Distributor (US) CIEPEC 2025.04.10-12 Beijing China SIGAS IE Expo SHANGHAI 2025.04.21-23 Shanghai China SIGAS korea chem 2025.04.23-26 South Korea Scotech Korea SIGAS Distributor (Korea) sensor-test 2025.05.06-08 Germany smartGAS Germany SIGAS subsidiary (Germany) DMS 2025.05.07-08 Malaysia BWTMS smartGAS Distributor (Malaysia) CHCC 2025.05.24-26 Wuhan China SIGAS / HEYER SIGAS as Distributor IPA convex 2025 2025.05.20-22 Indonesia PT-Namico smartGAS Distributor (Indonesia) Bari-Ship 2025.05.22-24 Japan IR System smartGAS Distributor (Japan) N-EXPO 2025.05.28-30 Japan IR System smartGAS Distributor (Japan) SmartSensing 2025.06.12-24 Japan IR System smartGAS Distributor (Japan) Sensors Converge 2025.06.27-29 US EOC smartGAS Distributor (US) STC 2025.07.16-17 Japan IR System smartGAS Distributor (Japan) JASIS 2025.09.03-05 Japan IR System smartGAS Distributor (Japan) SENSOR CHINA 2025.09.24-26 China smartGAS SIGAS subsidiary GSCC 2025.09.25-26 China SIGAS KORMARINE 2025.10.21-24 South Korea Scotech Korea SIGAS Distributor (Korea) CIOAE 2025.11.12-14 Hangzhou China SIGAS H2 meet 2025.12.04-07 South Korea Scotech Korea SIGAS Distributor (Korea) SIGAS 2025 Exhibition List 2025 smartGAS Exhibition List 2025 Southeast Asia Distributor PT-Namico(Indonesia)/ BWTMS(Malaysia)Exhibition List 2025 Korean Distributor SCOTECH Exhibition List 2025 Japan Distributor IR SYSTEM Exhibition List 2025 US Distributor EOC Exhibition List

Read More20